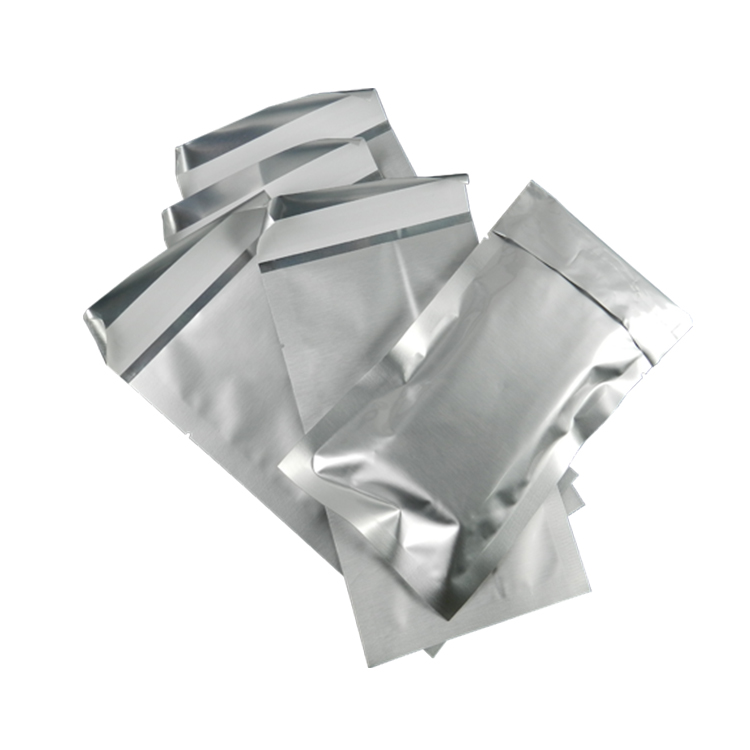

Aluminum foil bags must be the most common bags use for high

barrier products packaging, like coffee, tea, or some airtight and

high puncture resistance products. Sometimes looking for the most

ideal packaging formats for your product can be a merely

challenging task especially when you need a multi-layer structure

design.

Aluminum foil bags made with 3 or 4 layers high resistance

material, normally it will have one layer aluminum foil or

metalized film in the middle of it to keep the products reach out

of sunshine or direct light, this will keep products with longer

shelf and have higher barrier properties.

- FDA approved material and BPA free products

- Highly durable, long shelf-life for products, against UV light,

moisture, and oxygen

- Good for chemical or products need keep reach out of light

- MOQ start from 100 pcs with lower cost

- Suitable for coffee, tea, pet food or premium products packaging

- Can be added with zipper, valve, laser scoring, window

FAQ

Frequently asked questions

Is Sunkey a trading company or manufacturer?

We are 100% manufacturer specialising in flexible plastic

packaging. Our facility is in Jiangsu Province, Wuxi City.

Can you recommend a material structure for my packaging needs?

Yes, kindly provide us with the information of your packaging

contents and its weight and we will recommend a material structure

that suits your requirements.

What’s your MOQ?

Your first order should cover 5,000 square meters of film while

subsequent orders 10,000 square meters of film.

How long will I have to wait for my bags to be delivered?

The delivery time is usually 20 days. However if you need it

delivered urgently, please inform us in advance.

How soon can I receive a quotation?

We will make an offer within 24 hours. For urgent matters, kindly

dial our number or e-mail us and we will response back within 5

minutes.

What certifications does Sunkey Plastic Packaging have for its food

and medicine bags?

Certifications include ISO, and five drug packaging certificates

that qualify our bags are food grade.

How can your printing press ensure the printing precision of bags?

Our manufacturing facility has five printing press and able to

print up to 12 colors. Moreover, the printing speed of our machines

is 180m per minute with printing precision within 2.0mm.

What types of bag can you manufacture?

Our packaging solutions consist of three-side seal bags, back seal

bags, pillow bags, stand-up bags, stand-up zipper bags and stand-up

bottom bags.

Can you customise zipper bags to my requirements?

We provide packaging solutions and are committed to customising

packaging bags for our customers.

What types of glue do you use for lamination?

We use German Henkel polyurethane glue to ensure superior strength

and vacuum preservation.

What are the production process stages?

Printing, laminating, curing, slitting, bag-making, packing,

inspection, shipping